Coating

Coating

Our coating services

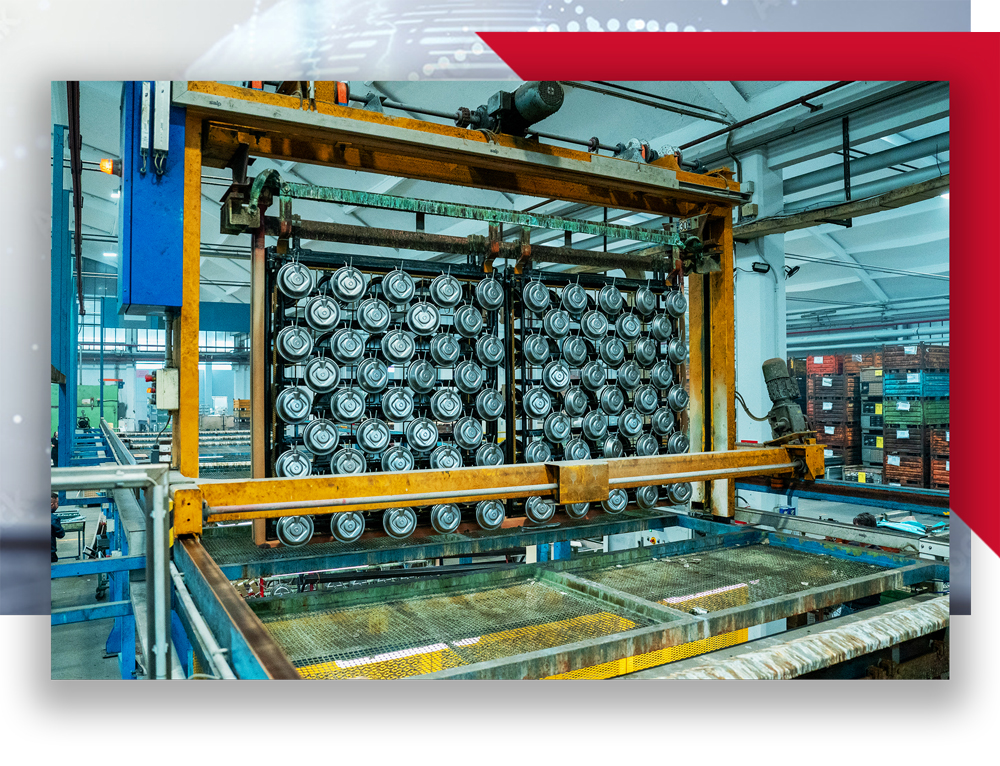

Our coating division is the main division in terms of volume worldwide; Depending on our locations we offer different type of line technologies with different type of coatings, including Zinc, Zinc Flake and Zinc Nickel. Our lines, depending on location and market demands, can vary from operating with Dip-Spin baskets, E-Coat, manual rack and Reel to Reel just to name a few.

Barrel

|

|

|

|

|

|

|

|

Dip Spin

|  |  |

|

| ||

Rack

|

|

|

|

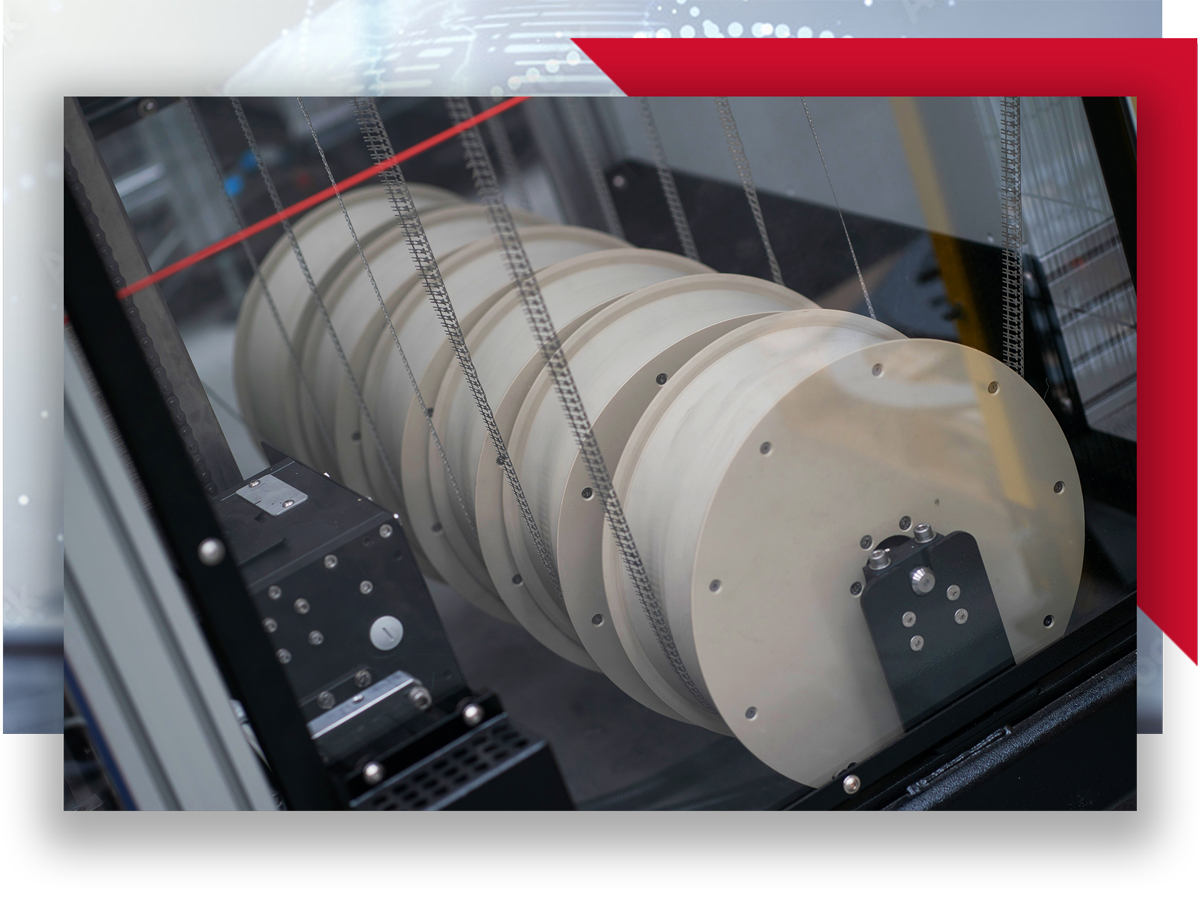

Reel to Reel

|  |  |

|

Our treatments

The Electro-painting process for either Anodic or Cathodic E-coat black paint typically consists of a zinc phosphate pre-treatment, followed by the bulk, barrel high-voltage electro-deposition of either the anodic or cathodic paint resin systems.

TREATMENT CARRIED OUT BY

Proper surface preparation is the first step in the metal finishing process and critical to the overall coating system performance. Bulk processing barrel phosphate lines apply the required zinc or manganese phosphate material layer to the parts before coating.

TREATMENT CARRIED OUT BY

|  |  |

Organic and inorganic solvent or water-borne coatings containing dispersed and binding Zinc and Aluminium are applied through dipping or rack, centrifugation, and polymerization. They provide electrical isolation (with an organic top coat) and excellent corrosion resistance.

TREATMENT CARRIED OUT BY

|  |  |

|  |  |

Alkaline coating applying a zinc-nickel alloy with 12-16% nickel content through barrel or rack electrolytic plating. The zinc-nickel alloy depositions, with different passivation processes, represent the best the new metal surface protection technology can offer.

TREATMENT CARRIED OUT BY

|  |  |

|  |

|

|

|

Excellent corrosion resistance, availability on barrel lines, and compliance with all the leading car manufacturers’ technical standards are the key features of Stainless-Steel Passivation.

TREATMENT CARRIED OUT BY

|  |  |

Our treatments

Proper surface preparation is the first step in the metal finishing process and critical to the overall coating system performance. Bulk processing barrel phosphate lines apply the required zinc or manganese phosphate material layer to the parts before coating.

TREATMENT CARRIED OUT BY

Alkaline coating applying a zinc-nickel alloy with 12-16% nickel content through barrel or rack electrolytic plating. The zinc-nickel alloy depositions, with different passivation processes, represent the best the new metal surface protection technology can offer.

TREATMENT CARRIED OUT BY

|

Alkaline coating applying a zinc-nickel alloy with 12-16% nickel content through barrel or rack electrolytic plating. The zinc-nickel alloy depositions, with different passivation processes, represent the best the new metal surface protection technology can offer.

TREATMENT CARRIED OUT BY

|

Thanks to different passivation, the alkaline or acid zinc depositions provide high protection to metal surfaces against weather stress corrosion. The deposits have excellent corrosion resistance, although they undergo thermal shock.

TREATMENT CARRIED OUT BY

|

Excellent corrosion resistance, availability on barrel lines, and compliance with all the leading car manufacturers’ technical standards are the key features of Stainless-Steel Passivation.

TREATMENT CARRIED OUT BY